Your Prototyping and Small Project Partner.

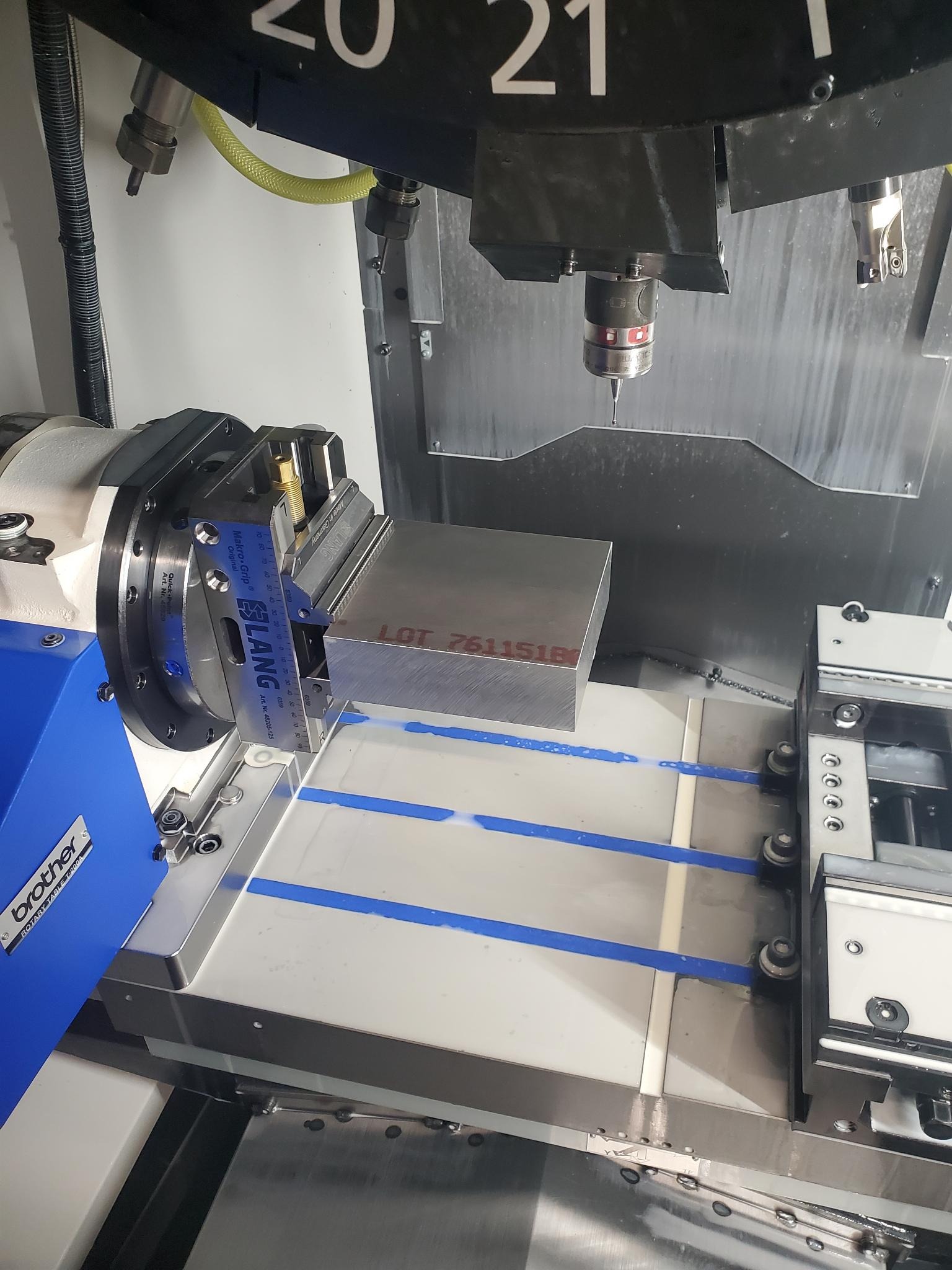

With capabilities ranging from 4-Axis CNC Milling and 2-Axis CNC Turning, to manual turning and milling, TIG welding, in-house CMM and quality laboratory, and CAD/design work, we can be your one-stop shop for anything from one-offs to contract runs. We can support your product development through production.